All you need to know about upright stillage

We’ve been asked several times about how effective an upright stillage system is. We got our guru Mark Tetlow to write down a few pointers as guidance as to the challenges.

Upright stillage versus flat stillage

In a majority of cases, upright stillage is used when there is limited cellar space so the widest offering possible is achieved. However, this method does have a few potential problems, which it is useful to be aware of:

- It is difficult to adequately clean the siphon so you run the risk of infecting the beer.

- Wastage is higher because the bottom of the cask has a smaller surface area than the side, meaning yeast sediment has less opportunity to settle and compact efficiently. It can also be difficult to judge where the yeast is, so run the risk of pouring cloudy beer or not getting all of the clear beer out.

- There is no way to sample the beer easily, so once it’s connected you can only tell how good the beer is once you have poured it. If it’s not right you then have a line full of beer going to waste.

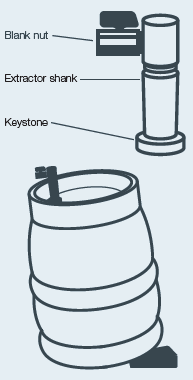

Broaching

Upright stillage removes the opportunity to tilt the casks. What must be done instead is known as broaching. Use a 2.5cm (1 inch) wedge and place it under the cask, to tilt the beer away from the keystone. All casks must have an extractor shank fitted with a blank nut, which should be driven through the keystone between 4 and 8 hours after delivery.

Venting

Whether your casks are in vertical or flat stillage, don’t forget to vent them. For casks in vertical stillage, excess pressure must be vented from all casks by opening the valve in slow, gradual steps, until fully open. Either vent through a valve or use a new, clean, soft peg.

Dispense

Always

- Put wedge on opposite side to tilt cask towards the shank/keystone, taking care not to disturb the sediment

- Insert a clean hop seed filter between the tap and the beer pipe

- Close vent and beer valve at end of each session

Never

- Handle area of extractor tube that comes into contact with product

- Move cask once it has been broached

Although upright stillage is doable, the best (and with the least faff) way is to use flat stillage with automatic tilters. You want the best yield possible and casks are designed so that the yeast sits beneath the cap. If vented and conditioned correctly you should only ever get 1/2 to 1 pt of wastage.

A few considerations for cleaning the lines

Whatever stillage system you have adopted, nothing is more effective than a good old manual clean. It’s the easiest and most effective clean, and if you follow these pointers you can be confident of a quality serve:

- Always flush through with water before line cleaning.

- Put line cleaner into the lines, leave for 10 mins, pull through fresh cleaner and leave for 10 mins. Do this three times so that the yeast is rinsed out of the system.

- Don’t leave line cleaner in without flushing through or you won’t get a good clean.

- Invest in good quality cleaning chemicals – it pays dividends in that it goes further and helps you to maximise yield. All round more bang for your bucks!

If you have any questions about any aspect of cellar or bar management that we can help you solve, just ask the Cellar Craft guru below.

Have a question or a problem?

If you have a problem or a question then fill in the form below and the Cellar Craft guru will get in touch to talk through everything and come up with the best solution for you. The best or most informative questions may also be used in articles on our site to help all our readers.