The Ten Rights of Cask Beer

1. Get the Quantity Right

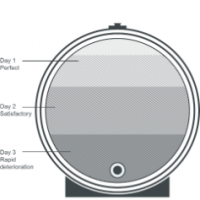

When placing an order with the brewery, you should only aim to buy casks in a size that you can sell out within three days of the cask being tapped.

When casks are in service they are exposed to the air (the hard peg is removed to prevent a vacuum forming inside the cask which would make it impossible to pull beer up to the bar with the beer engine), and beer exposed to the air will begin to oxidise. Oxidised beer will have a flatter, duller, less pleasant taste which will give your bar a reputation for serving bad or poor quality beer.

2. Keep it Right

How you store your beer is very important. It should always be kept in the cellar at 11-13ºC (51.8-55.4ºF). Never store your beer outside. Cask ales are live and start to undergo secondary fermentation when you peg & vent them. As such, they need to be stored correctly; if the temperature is too cold then the yeast will not be activated when the cask is vented and this will prevent the proper flavours, aromas and the CO2 from being produced, creating an odd tasting, unpleasant, flat drink. In reverse, too high a temperature and the beer will become over-conditioned creating flavours that are too strong and overpowering.

3. Store it Right

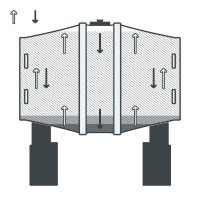

When it arrives in the cellar cask beer should be immediately stillaged. This creates an air-pocket around the shive to allow for proper conditioning. Cask beer contains an additive called finings, which cause all of the protein, yeast and brewery sediment to settle in the bottom of the cask giving a clear crisp look (also known as coming bright).

4. Peg and Vent it Right

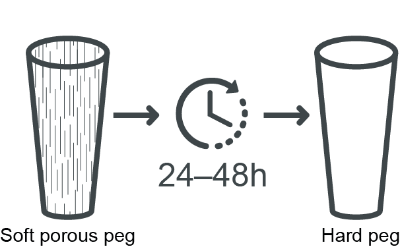

Around 24 hours after you have stillaged the cask you should begin the process of pegging and venting. This allows the process of secondary fermentation to begin. This is the start of the beer’s development of the unique flavour, aroma and mouth-feel profiles unique to each cask.

Make sure to clean the shive with a good food safe sanitiser to prevent bacterial infection. Likewise, only use new clean soft and hard pegs for each cask (they should come with your delivery). The soft peg should be left in the shive for 24-48 hours until all of the gas has stopped escaping then replaced with the hard peg.

5. Condition it Right

Like making the perfect wine, the best bread, or creating a quality musical instrument, the best beer needs time to develop. Allow the cask to condition for up to 10 days after venting (if you can), this will allow for the rich aromas and deepest flavours to develop. The longer you can leave a cask (up to 10 days) the better it will develop and taste.

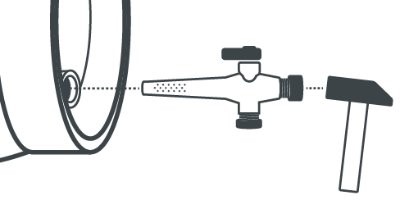

6. Time the Tapping Right

After you have waited as long as you can for the beer to condition then your beer should be tapped. 24 hours before you want to serve your beer give the keystone a good clean with a food safe sanitiser and use a clean dry tap (always make sure taps are cleaned between casks). Leaving tapping as long as possible helps to prevent any bacteria from getting into the cask and causing off tastes and odours.

7. Make Sure it’s Right

After tapping but before hooking the cask up to the beer lines take a small sample of the beer. Check it for clarity (does it look clear, clean and bright?), check the aroma (does it smell right?) and finally check the taste. If you are happy then pop a clean and dry hop filter onto the connector of the tap, hook up the beer lines and open the tap, pull beer through the lines and in the bar check the three characteristics again. If all is OK then your beer is ready to serve.

8. Sell it Right

Every time you put the cask into service the hard peg has to be removed. This allows air to be drawn into the cask with every pull of the beer engine handle. The addition of the air into the cask causes the beer to oxidise and age, so make sure you can sell all the beer within three days of starting service.

Also, remember to put the hard peg back in the cask finger tight each night or at the end of each service and turn off the cask tap, this will help to slow down the rate of oxidation/ageing.

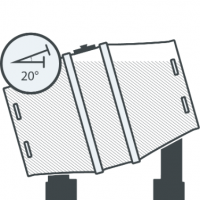

9. Get the Angle Right

When you have sold two thirds of the beer you should gently tilt the cask forwards so that its rear end is about 7cm (2-3 inches) higher than the front. This allows all of the beer to be sold from the cask without disturbing the sediment at the bottom of the cask, maximising profit with minimal waste. Tilting should be done at the end of a service session to allow any sediment that is disturbed to re-settle and not end up in your customers’ glass!

10. Clean it Right

As we have said before cask beer is a live product, containing lots of yeast and beneficial bacteria. These can still give you issues if allowed to get out of control, therefore you should clean your cask lines at a minimum interval of every 7 days. Use a quality line cleaning product, cheap line cleaners may seem cost effective but can end up costing you more due to poor performance.

If you are experiencing any problems in delivering the perfect serve and would like some expert advice, just Ask CellarCraft

Download the entire CellarCraft guide